Photovoltaic inverter trough box manufacturing process

Solar panel manufacturing process: from cell to module

This is the so-called lamination process and is an important step in the solar panel manufacturing process. Finally, the structure is then supported with aluminum frames and ready is the PV

Technology of Solar PV Panels, Energy, Cells, Lantern, Cooler, Light

Technology of Solar PV Panels, Energy, Cells, Lantern, Cooler, Light System, CFL Inverter, Photovoltaic System, Power Plant, Water Heater, Collector, Solar Cooling, Refrigeration, Solar

Modeling Photovoltaic and Concentrating Solar Power Trough

performance of photovoltaic modules and inverters. This paper presents an overview of each PV and inverter model, introduces a new generic model, and briefly discusses the concentrating

HANDBOOK ON DESIGN, OPERATION AND MAINTENANCE OF SOLAR PHOTOVOLTAIC

2.2 PV Modules 3 2.3 Inverters 3 2.4 Power Optimisers 4 2.5 Surge Arresters 4 2.6 DC Isolating Switches 4 2.7 Isolation Transformers 4 2.8 Batteries (for Standalone or Hybrid PV Systems) 4

Low‐voltage ride‐through control for photovoltaic generation in the

1 Introduction. The photovoltaic (PV) generation is a promising alternative of the conventional fossil fuel-based power plants while great challenges of its large-scale grid

A Comprehensive Guide to Solar Panel Manufacturing

Solar Panel Manufacturing: Understanding the Process. Here are the main steps that outline the solar panel manufacturing process: 1. Solar Cell Sorting. Solar cell sorting will allow the manufacturer to sort the solar cells available for

Control and Intelligent Optimization of a Photovoltaic

An important technique to address the issue of stability and reliability of PV systems is optimizing converters'' control. Power converters'' control is intricate and affects the overall stability of the system because of the

Manufacturing Facilities 900V Grid Connected class Photovoltaic

Photovoltaic Central Inverter. Manufacturing Facilities Osaka Plant (Small & Middle power equipment). The "Photovoltaic Central Inverter" is a "Gird-Connected Synchronous Inverter",

Economical comparison between Photovoltaic Panels and Parabolic Trough

from photovoltaic, it is considering both little installations distributed for the auto-consume and high power plants for the electrical energy selling. The principal difference between both

Role of solar PV in net‐zero growth: An analysis of international

In this context, the European Union (EU) and China play a key role, being two important PV value chain players committed to reaching carbon neutrality by 2050 [] and 2060

Photovoltaic (PV) Module Technologies: 2020 Benchmark Costs

incurring additional costs (Figure ES-3). Perovskites can also be combined with other PV technologies in multijunction configurations. We estimate an MSP of $0.31/W for perovskite-on

Solar panel manufacturing process: from cell to

Solar panel manufacturing process: from cell to module. During lay-up, solar cells are stringed and placed between sheets of EVA. The next step in the solar panel manufacturing process is lamination.

PV Solar Cell Manufacturing Process & Equipment Explained

Step-by-Step Guide to the PV Cell Manufacturing Process. The manufacturing of how PV cells are made involves a detailed and systematic process: Silicon Purification and Ingot Formation:

Photovoltaic modules, inverters and systems Position on the

Performance requirements on quality, durability and circularity for inverters (2.4) Repairability requirements for inverters On-site repairability measures should concern inverters up to 150

Solar Inverter Cost Analysis from Manufacturing

The manufacturing of solar inverters is an intricate process, involving a detailed and multifaceted cost structure. Every aspect, from the choice of materials to the final assembly, plays a significant role in determining the

Solar Junction Boxes: Beyond Basics to Bypass Diodes

This comprehensive guide is compiled to recognise, explore, and explain its utility, function, and ore manufacturing process. Here is everything one needs to know about the solar junction boxes that focus on reducing solar

Design and Evaluation of a Photovoltaic Inverter with Grid

inverter and control as a black box. In this manner, the inner-workings of the inverter need not be known, especially since it is proprietary information of the manufacturer, and the 3.18 PV

6 FAQs about [Photovoltaic inverter trough box manufacturing process]

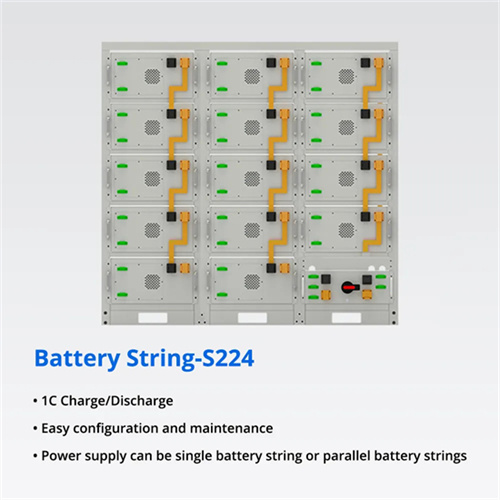

What is a string box in a photovoltaic plant?

String Box. String Boxes represent one of the most important elements in a photovoltaic plant. They are grouping boxes of strings, designed to convey the electricity coming from the photovoltaic strings and direct it to the inverter which will convert the current from direct to alternating.

How does a photovoltaic inverter work?

They are grouping boxes of strings, designed to convey the electricity coming from the photovoltaic strings and direct it to the inverter which will convert the current from direct to alternating. These boxes are placed in the field, usually hooked to poles of the support structures of photovoltaic panels.

What is a photovoltaic (PV) manufacturing process?

The photovoltaic (PV) manufacturing process is the first step in the production of solar panels. This process involves the fabrication of PV cells, which are made up of semiconductor materials such as silicon. The operator cuts the cells into small squares and places them on a substrate.

What is a photovoltaic system PV module?

Photovoltaic systems PV modules are manufactured by assembling an array of solar cells. The most common PV modules today have a power capacity between 300 and 500 W, which corresponds to an area between 1.5 and 2.5 m 2, assuming 20% module efficiency ( Fig. 1.3 ).

How are solar PV modules manufactured?

PV modules are manufactured by assembling an array of solar cells. The most common PV modules today have a power capacity between 300 and 500 W, which corresponds to an area between 1.5 and 2.5 m 2, assuming 20% module efficiency ( Fig. 1.3 ). Solar PV at different scales

What is a PV junction box?

The PV junction box is a specific structural form that combines electrical design, mechanical design, and material science into one complete design. It connects the power generated by solar cells to the external line. Many components boost the efficiency of the solar panel.

Related Contents

- Aotai photovoltaic inverter production process

- Semi-flexible photovoltaic panel manufacturing process

- Photovoltaic inverter heat dissipation process

- Solar panel photovoltaic panel manufacturing process

- Photovoltaic inverter power generation process diagram

- Photovoltaic inverter combiner box

- Huawei photovoltaic inverter foundry

- The photovoltaic inverter is not lit

- What does 5gw photovoltaic inverter mean

- Photovoltaic inverter processing manufacturers

- Photovoltaic bracket selection process drawing

- Energy storage inverter photovoltaic material manufacturer